12/08/2024

What is the link between glass packaging and the Rs in the Circular Economy?

By Millena Araújo and Arlene Carvalho, from Circular Movement

Have you ever thought that many glass containers, which used to be packaging, are commonly repurposed for different purposes? Examples include beverage bottles, food jars, and in some cases, even medicine, cosmetics, or perfume bottles. This happens because glass is an extremely versatile, durable, inert material (where there is no exchange of substances between the product and the container), easy to clean, and consequently reusable — one of the main tenets of the Circular Economy. Its aesthetics often make it an attractive object for decoration, storage, or crafts.

This type of material use is called domestic and is very common in Brazil, possibly lasting decades in people's homes, according to Caroline Morais, manager of Institutional Relations and Sustainability at the Brazilian Glass Industries Association (Abividro). There is also industrial reuse of glass packaging.

“Returnable packaging is Circular Economy par excellence, and glass is a powerful ally. They are reused by the industry for long periods - since glass is a material made to be reused. With this, it contributes significantly to sustainability, both in our homes and on a large scale in the industry,” she points out.

For this reuse to happen on an industrial scale and for the packaging to be returnable, Morais explains that glass packaging can be reused by reinserting it into the production line.

"Bottles, already filled with products, are transported to bars and restaurants, where they are stored until consumed. After consumption, these packages are reserved until the company collects them. They leave the consumers and are sanitized and refilled. Often, this cycle is done for more than 10 years. Moreover, when returnable glass bottles are reused, we directly reduce the CO2 emissions from the product life cycle, supporting the fight against climate change,” she emphasizes.

We have already seen that glass has enormous value in terms of reuse, especially regarding packaging and glass bottles in the beverage industry. But in addition, how about exploring a little more of the potential and also the challenges of this material concerning other Rs of the Circular Economy?

Glass Recycling

For Prof. Dr. Edson Grandisoli, ambassador and pedagogical coordinator of Movimento Circular, glass is one of the most used materials in the world, and its recycling and reuse are essential to generate less waste and save natural resources and energy.

“Sand is the primary source of silicon dioxide (SiO2) - essential for glass production. However, the world’s sand reserves are being depleted in different locations. A 2022 study by Leiden University in the Netherlands warned that sand demand is expected to increase by 45% in the next four decades. Therefore, rethinking practices within a Circular Glass Economy is more than essential and urgent,” he says.

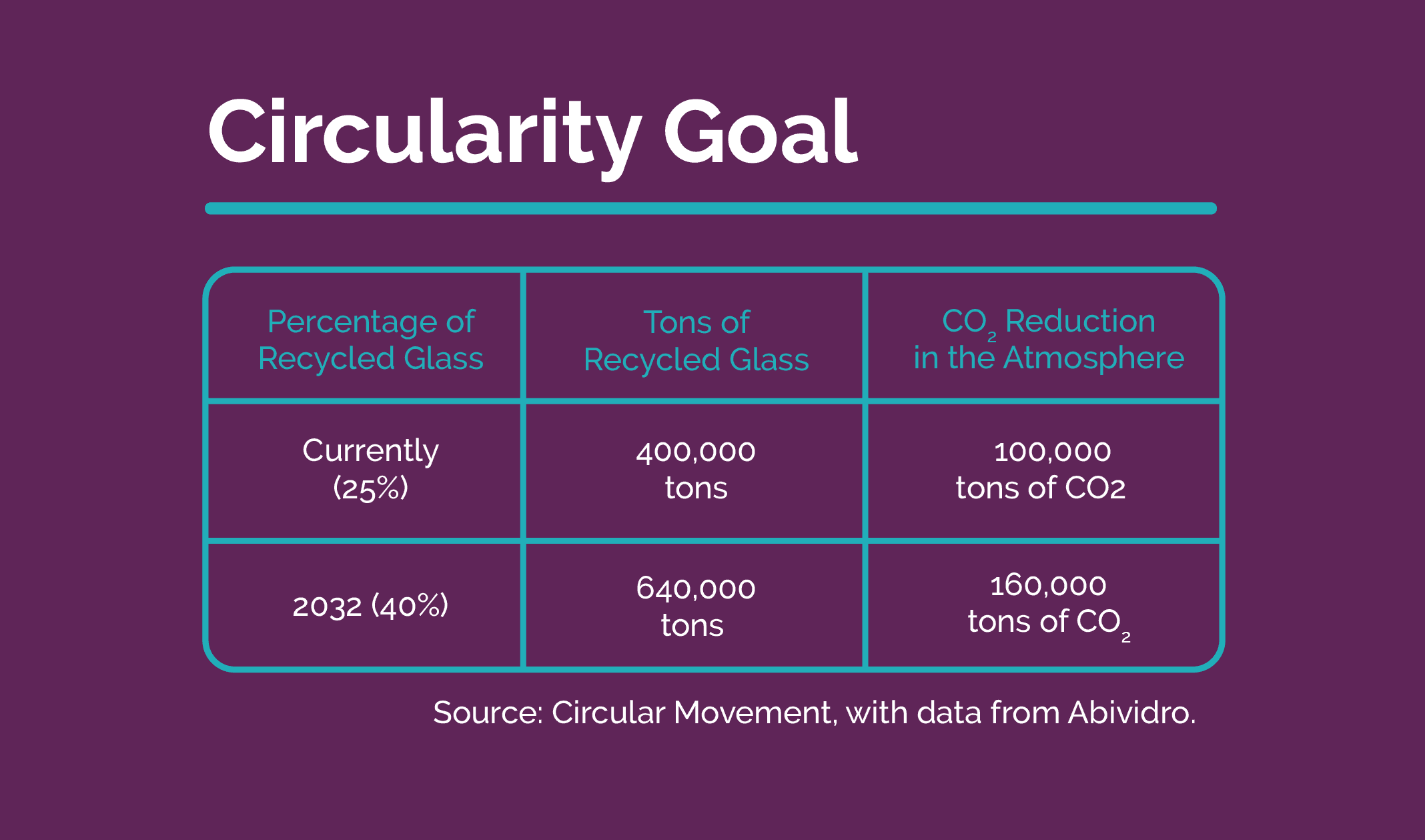

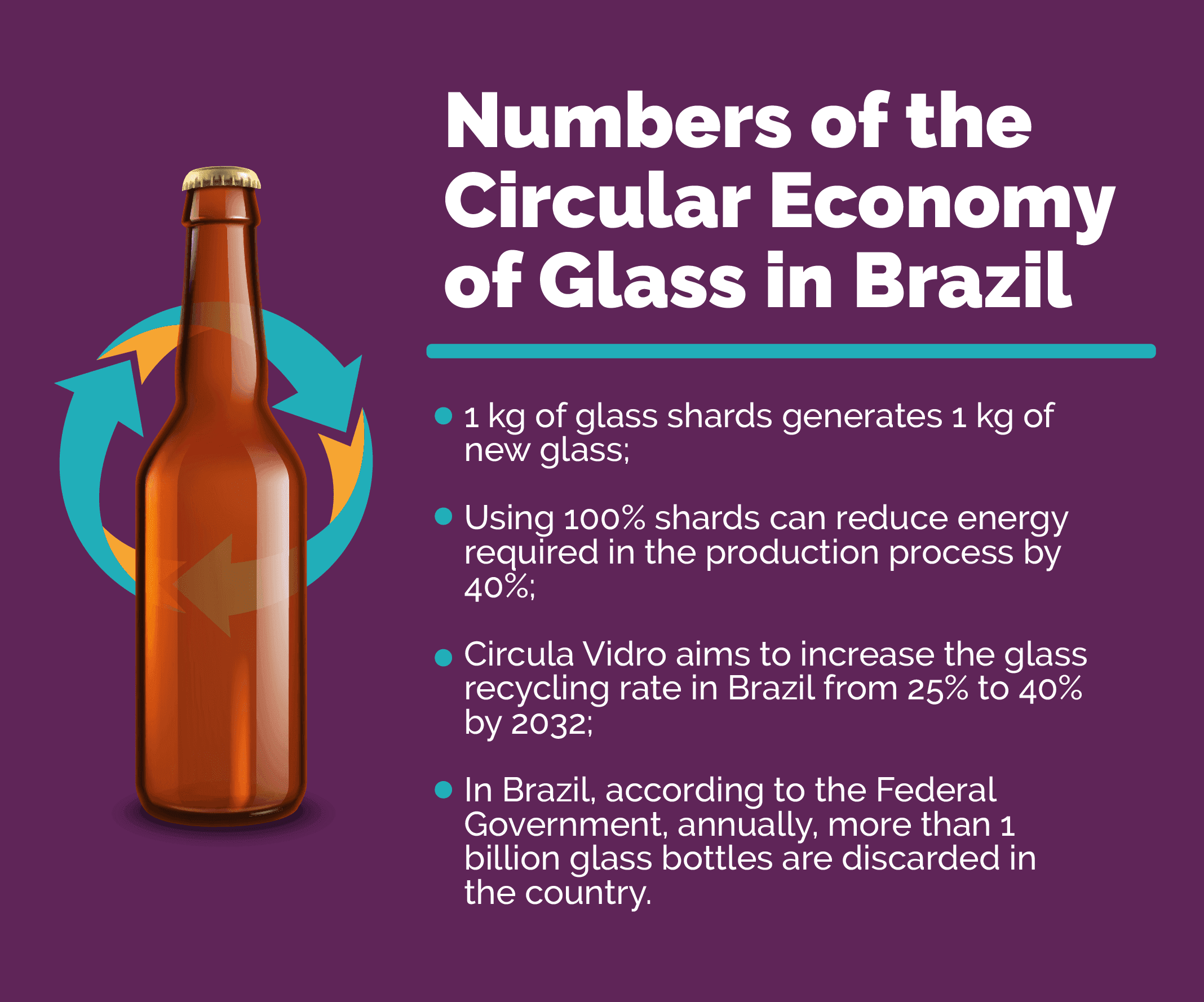

Glass can be recycled countless times without losing quality in the recycling process, meaning 1kg of glass cullet produces 1kg of new glass. Currently, more than 400,000 tons of the material are recycled per year. And this represents about 100,000 tons of CO2 less in the atmosphere during the period.

“Using cullet makes production more efficient, which is why it is estimated that 100% cullet allows reducing the energy used in the process by 40%.”, points out Abividro’s manager, Caroline Morais.

Valuing natural resources, optimizing energy use, and creating new opportunities for different societal actors are benefits that can be generated from glass circularity, in addition to contributing to less waste generation.

“Glass has enormous potential to be reused or recycled, the basis of a more circular economy. Its recycling can generate jobs, help conserve the environment, and still be profitable for the different actors in the chain,” concludes Grandisoli.

In Brazil, according to public management, more than 1 billion glass bottles are discarded in the country annually, showing the enormous economic potential still to be explored. Data from Abividro in 2020 indicated that glass recycling in the country moved approximately R$ 120 million per year.

It is expected that Circula Vidro, the entity managing glass reverse logistics in Brazil, will expand the expected economic and environmental benefits with the expansion of glass packaging recycling in Brazil.

“We adopted a free trade system among operators, which guarantees greater efficiency in the process. If the use of recycled glass is more economical than production from raw material, both packaging and final products will have more competitive prices, benefiting collectors and logistics operators. This reduces transaction costs, benefiting everyone, including the end consumer. Environmentally, there will be less waste in inappropriate locations and a reduction in carbon emissions when using recycled glass instead of raw material,” explains Circula Vidro’s CEO, Fabio Ferreira.

Adhering to Circularity

Grupo Petrópolis, responsible for producing beers like Itaipava, Petra, and Black Princess, adheres to glass circularity in its production process. The Group’s glass packaging already has 60% recycled content, but the goal is to increase it more and more. Along with the National Service for Industrial Learning (SENAI), the brewery launched in 2022 the Strategic Mission for Glass Circularity. The proposal was to develop solutions to expand and strengthen glass packaging circularity in the production and consumption chain, prioritizing technological, logistical, and economic alternatives. Grupo Petrópolis’s Sustainability and Continuous Improvement Manager, Alaercio Nicoletti, explains the plans to increase this number.

“In recent years, we have been taking effective actions to increase the percentage of recycled material in our packaging and, mainly, reduce the amount of materials used with the scientific method for continuous improvement actions. The main challenge of glass is the reverse logistics of post-consumer packaging since less than 4% of non-returnable bottles (such as long necks) are correctly disposed of. As it is a low-cost material – much lower than the prices practiced for aluminum, for example – with high weight and injury potential, glass is usually discarded in common household and point-of-sale waste.”

As opportunities, the manager highlights “the interest of the bottle industry, which imports glass cullet from Europe to meet the internal demand for broken bottles.” For him, there are still many benefits in re-educating consumers to use returnable packaging and correctly dispose of them.

“Ten years ago, we had expenses of around R$ 11 million for the disposal of our industrial waste in sanitary landfills. In 2023, we had revenue of R$ 30 million with the proper disposal of the same waste, generating revenue from the Circular Economy,” points out Nicoletti.

“Our product packaging is 100% recyclable and, if properly disposed of, can be reused by the industry through the Reverse Logistics process. In January of this year, we started the Glass Circularity Project, together with the National Confederation of Industries (CNI), to map the glass recycling chain. The project includes the efficient use of logistical routes through a digital platform that will operate collection and storage points. Post-consumer glass will be obtained through partnerships with bars and restaurants, condominiums, possible events, and universities,” complements the manager.

A differential of the initiative is that the waste will be processed at the collection moment, being reduced to glass cullet and directed directly to the main recyclers in the country with a generation of value from this material. Thus, the recovered waste can return to Grupo Petrópolis’s production cycle in the composition of bottles with recycled content.

Still according to Grupo Petrópolis, the Strategic Mission for Glass Circularity was created precisely to facilitate the glass reverse logistics process - as it, like other materials, faces some common challenges - such as difficulties in the selective collection process in many cities and the incorrect disposal of waste by the population.

“We believe that by seeking synergy with other agents, we can achieve our ambition to contribute to Brazil’s sustainable development,” concludes.

"The integration of all stakeholders and the synergy between them will be crucial in transforming recycling in Brazil. Cooperation, through the chaining of actions by all actors in the product life cycle, is necessary to achieve the goal of reverse logistics. Conversely, the absence of this coordination can lead to the system's malfunction, potentially causing the technical and financial collapse of reverse logistics. The individualized obligations of each actor in the chain result from their position in the import or manufacture, distribution, and commercialization of the product or packaging," emphasizes the representative of Abividro.

And the other Rs?

Besides Reusing and Recycling, the Circular Economy highlights other important Rs that can contribute to a more sustainable use of glass.

- Reducing consumption is one of the fundamental pillars: by opting for products with less packaging or using returnable glass packaging, the demand for new productions is reduced, and consequently, socio-environmental impacts are decreased.

- Rethinking the design and functionality of glass packaging can lead to innovative and sustainable solutions.

Companies can invest in models that facilitate reuse and recycling, while consumers can be encouraged to choose products that adopt these practices.

- Refusing non-recyclable packaging is also an attitude that reinforces circularity. By incorporating these Rs into daily life, both industries and consumers can collaborate for a more sustainable life cycle for glass.

The potential of glass in the circular economy is vast and promising. However, its full realization depends on a change in mindset and coordinated actions among all sectors of society. The effective implementation of reverse logistics for glass packaging in Brazil, now led by Circula Vidro and supported by initiatives such as the Strategic Mission for Glass Circularity of Grupo Petrópolis, among others, reflects the sector’s commitment to the Circular Economy.

The integration of all chain agents, including industries, governments, institutions, and consumers, is essential to achieving the established recycling goals. By promoting the reuse, recycling, and reduction of glass packaging consumption, the country not only protects the environment but also boosts the economy and fosters more responsible practices regarding natural resources.

Image: Thiago Egg/Movimento Circular

About Circular Movement

Created in 2020, Circular Movement is a collaborative ecosystem committed to encouraging the transition from a linear to a circular economy. The idea that all resources can be reused and transformed is the motto of the Circular Economy, the basic concept of the movement. Circular Movement is an open initiative that promotes collaborative spaces with the aim of informing individuals and institutions that a waste-free future is possible through education and culture, the adoption of new behaviors, inclusion, and the development of new processes, products, and attitudes. The work is done in partnership with Dow, a chemical, plastics, and agricultural products company based in Michigan, USA. Circular Movement currently impacts 2 million people through its activations and content.

And you? Do you want to learn more about Circular Economy?

If you are interested in learning more about this topic, access Circular Academy, the first free Latin American course on Circular Economy aimed at the general public. Together, in partnership and collaboration, we can make a difference in building a more circular planet.